Most steel lamp posts makers will meet such confuse. Light pole plate cutting and press brake bending are ok. Before welding, the pole shape is good. BUT after welding, factory gets a curved pole. What happened? What can be the reason? How to solve it?

In fact, such phenomenon is just one case of thermal expansion and contraction. Direct reason is unbalance internal stress welding or thermal cutting (flame cutting or plasma cutting).

Thermal expansion and contraction

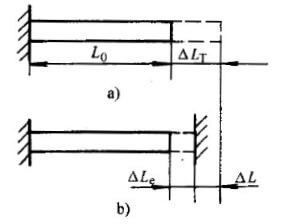

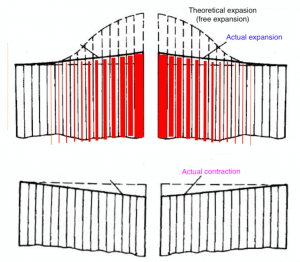

When steel pole plate (metal plate) is heated, it will expend. The expansion will be in all directions, X, Y, Z. while Visible to the naked eye will be on big part size direction. For our steel lighting column, it is length. If with outside force, expansion or contraction will be limited.

Elastic strain and plastic strain

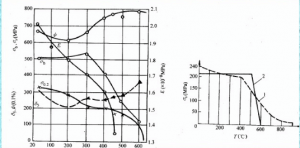

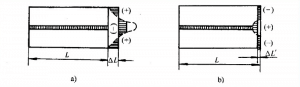

Steel plate has these two characters under thermal changing conditions. Steel melting point is about 1400 degree. Melt steel is liquid; there is no any strain. From elastic to plastic strain, distribution graph is like following. We suppose that less than 500 degree, steel yield stress is same like original. From 600 degree or higher, steel characters will be some like plastic material.

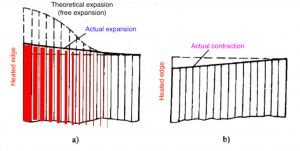

If without Interatomic force, steel plate thermal expansion will be like theoretical. Interatomic force is like outside force limited free expansion.

Thermal cutting or welding stress

Thermal cutting includes flame or plasma (even laser) cutting for steel light pole production. Conditions will be similar to welding process.

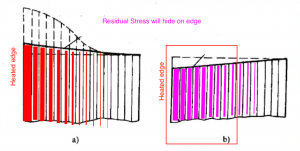

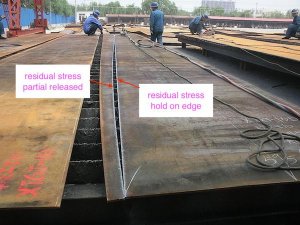

Residual Stress

The internal stress will not disappear with cut or weld finish. It will hide in the edge. It is waiting for some conditions to release.

Thermal deforming

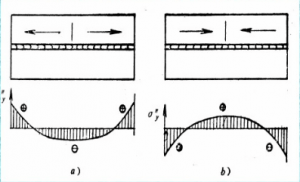

Thermal cutting or welding procedure can cover steel pole plate elastic and plastic strain. Such stress is very big and will affect on metal deforming. We can see that the edge will be shorter than before. If there is no force to balance it, we will get curved cutting or welding edge.

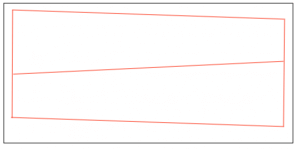

For thermal cutting, we can see that narrow plate curved by such inner force.

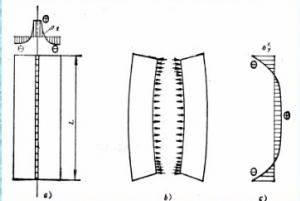

For steel light pole welding, we can see that ONE welding seam, small diameter pole curved into banana shape. even we do welding on steel light pole welding machine.

Steel lighting pole seam welding twist

Many steel lamp poles manufactures would like to use CNC light pole plasma cutting machine to prepare pole plate, because one machine can cover all parts cutting and can work automatically. But wrong process will make problems. Welding seam twist is typical phenomenon.

What makes welding seam twist?

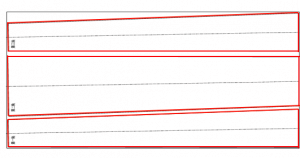

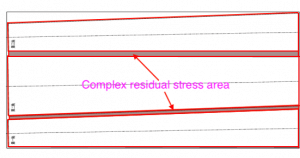

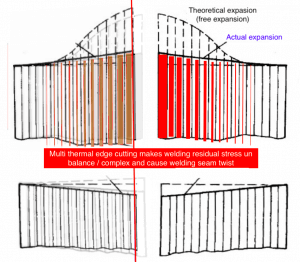

Too narrow edge cutting makes plate thermal stress superimposed and complex. If two different inner stresses weld together, welding seam two sides strain will be unbalance.

most problem is from conditions like above. to avoid repositioning errors, operator cut twice on narrow edge. It makes such edge inner thermal stress complex.

Complex means some part of plate heated on first cut. But then different cut happen on it again. thermal conditions are Superimposed.

If both welding edge has similar inner stress conditions, the steel pole welding seam will be straight. like above graph.

But if edge stress conditions is different, it will cause welding seam twist. two sides has different strain, different stress. Thermal expansion and contraction are complex.

How to solve this problem?

Our suggestion is to reduce factors on edge cutting. try to simplify cutting edge to reduce Superimposed stress on edge. we can optimize cutting route or use steel light pole taper plate slitting machine to cut plate.